Environmental Laboratory

UKAS Air Sampler Flow Calibration

May 08 2019

Involved with air sampling regulatory or compliance measurements to OSHA, NIOSH, ASTM, ARCA, CAR 2012 or HSG 248 standards then you should be gaining UKAS accredited calibrations for your master air flow sampling system. Regular UKAS accredited calibration of your air sampler system whether this be a flowmeter, flow calibrator or pump will ensure your sampling system remains compliant and accurate. All air sampler flow calibrations whether this be your working flowmeters or master flowmeters should have a complete line of traceability from a UKAS accredited calibration laboratory with a flow measurement uncertainty analysis to include in your overall measurement uncertainty budget. During calibration the air sampler flow rate is checked to ensure the volume flow rate of air is consistent with the instrument specification and upon completions a detailed certificate of calibration is issued inline with ISO/IEC 17025.

Air Sampling Methods and Procedures

Air sampling in practice draws a known volume of air through a sampling medium using a sampling pump and meter and is vital to any environmental monitoring program. For sampling of particulates, fumes, dust, trace metals and pollen the medium is generally a filter paper, as these contaminants are of solid material in the around µm to mm range, as anything larger would be too heavy to remain on the air and would fall to the ground. Sampling flow rates range from 50 ml/min up to 40 l/sec for high volume sampling. Sampling for gases, solvents and vapours instead of using a filter papers, or sometimes in addition would use a sorbent tube or impinger method, where sampling flow rate are much lower in the order of 10 – 100 ml/min. Calibration procedures, methods and sampling flowrates are specified in each standard such as NIOSH, EPA, HSG 248, OSHA, AHERA, ISO 13137 and MDHS, along with the calibration intervals for working flowmeters and master flowmeters. Personal sampling pumps must adhere to ISO 13137:2013 and are generally battery operated and bodily worn with the sampling inlet positioned in a manner which reflects the users' airborne environment and they must also comply to the standard specification for flow stability and pulsation limits. Flow calibration of the sampling pump system is completed before and after every sample run to calculate the average sample volume. This system calibration is generally completed by the user with a suitable UKAS accredited calibrated reference flowmeter.

Parameters

- Dust Sampling

- Coal Mine Dust

- Asbestos

- Toxic Gases

- Vapour Sampling

- Impinger Sampling

- Isokinetic

- Pollen Sampling

- Trace Metals

- Particulate

- PM-10 PM-2.5

- Cleanrooms

- Roadside

- Atmospheric

- Microbiological

- ISO 13137

Instruments

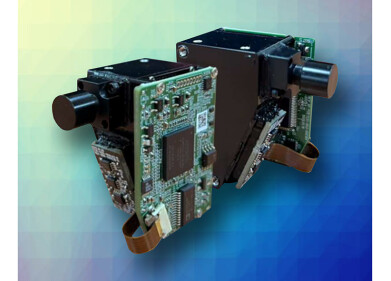

- SKC Air Samplers Pumps

- FJ Speciality

- Gilian Gilair

- JS Holdings

- Casella

- AP Buck

- Turnkey

- Airbox Variflow

- Tisch

- Zefon

- MESA BIOS

- Wagtech

- Microsensor

- TSI

- Escort

- Hi-Q Environmental

Digital Edition

IET 34.2 March 2024

April 2024

Gas Detection - Biogas batch fermentation system for laboratory use with automatic gas analysis in real time Water/Wastewater - Upcycling sensors for sustainable nature management - Prist...

View all digital editions

Events

Apr 30 2024 Melbourne, Australia

Apr 30 2024 Birmingham, UK

May 03 2024 Seoul, South Korea

May 05 2024 Seville, Spain

May 06 2024 Minneapolis, MN, USA