Environmental Laboratory

Protecting Saskatchewan lakes from contamination

Oct 28 2020

Using the Canadian Light Source synchrotron, a University of Saskatchewan-led research team has developed a method for monitoring uranium contaminants in mine tailings using samples from McClean Lake, SK.

While mining companies work to extract as much uranium as possible from processed ore, small amounts remain in the solid and liquid residue—called tailings—left over from the milling process.

To protect the downstream environment from potential impacts of the solid waste, the Canadian Nuclear Safety Commission requires companies to monitor the chemistry of uranium and other potentially harmful elements in their tailings facilities.

Numerous researchers have studied the chemistry of nickel, arsenic, selenium and molybdenum in Orano Canada’s tailings management facility at McClean Lake, but to date little was known about residual uranium. One of the challenges has been the extremely low concentrations of the element left after processing at Orano’s ore mill, which began operating in 1997.

Now researchers at USask and Orano Canada have developed a method for determining precisely where uranium is located in the McClean Lake tailings and its chemical form. The findings have just been published in the Journal of Spectroscopy and Related Phenomena.

Orano and other mining companies can now take the novel methodology this team has developed and tailor it to answer questions they have about the impact of their operations.

“Our findings provide Orano with the tools for monitoring how their tailings are changing over time,” said USask geological sciences professor Andrew Grosvenor.

“With this method, they can make informed decisions about whether they need to change their milling process or change the chemistry of the tailings, so that there is no impact on the surrounding environment.”

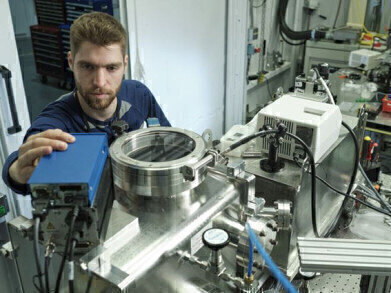

The researchers used a technique called X-ray microprobe which involves focusing a beam of light on the sample to “excite” the chemical elements that are present. When they are stimulated by the energy in the light, the elements emit X-ray fluorescence (XRF) signals that can then be captured in an image similar to a heat map, showing where they are situated.

USask chemistry researcher Arthur Situm, lead author on the team’s recently published paper, says a challenge their team had to overcome is that XRF signals emitted by potassium overlap with those given off by uranium—making it difficult to pinpoint the exact location of the uranium in a sample.

The team had a breakthrough when they identified the precise energy that excites the uranium in the McLean Lake tailings sample without also exciting the potassium, which is present in far greater concentrations.

“We found that to do this analysis most effectively, it’s best to tune the excitation energy to be above what you actually need to get excitation of uranium, but below potassium,” says Situm.

Using a technique called XANES at the CLS, the team was subsequently able to confirm that their method accurately identified the location of uranium in the tailings. The researchers also used XANES to determine the chemical form of the uranium, a first for the McClean Lake facility.

Grosvenor, corresponding author on the paper, says the SXRMB beamline at the CLS enabled the team to access all of the excitation energies they required for the study and to generate high-quality microprobe maps and XANES images.

“The study we performed required a tunable source of electromagnetic radiation with a high brightness,” says Grosvenor. “This was needed so that we could collect maps using different excitation energies and so that we could study the distribution of uranium in the tailings, which is found at low concentrations.”

Digital Edition

IET 34.2 March 2024

March 2024

Gas Detection - Biogas batch fermentation system for laboratory use with automatic gas analysis in real time Water/Wastewater - Upcycling sensors for sustainable nature management - Prist...

View all digital editions

Events

Apr 17 2024 Guadalajara, Nexico

Apr 18 2024 Shanghai, China

Apr 22 2024 Hannover, Germany

Apr 22 2024 Marrakech, Morroco

Apr 23 2024 Kuala Lumpur, Malaysia