Gas Detection

Is your sensor fail-safe?

May 16 2018

According to Wikipedia, fail-safe in engineering is “a design feature or practice that in the event of a specific type of failure, inherently responds in a way that will cause no or minimal harm to other equipment, the environment or to people”. In other words, a fail-safe system is designed to avoid situations where a fault which prevents the system itself from performing its safety function goes undetected.

This, of course, is of the utmost importance in gas detection, where worker’s lives and property safety are at constantly at stake. Having a sensor failing to indicate its failure may lead to the inability to detect an alarm condition with potentially dramatic consequences. Hence, the need for frequent, even daily, bump tests on gas detection technologies that are not inherently fail-safe.

The most frequent cause of sensor failure on technologies such as Metal Oxide Semiconductor (MOS) and Catalytic (or pellistors), other than progressive wear, is the exposure to inhibitors and poisons causing the sensor to enter a condition unresponsive to the target gases.

Dual-beam/dual detector Infrared sensors such as N.E.T.’s IRNET, IRNEX and IREF provide instead a fail-safe means to detect when a fault condition arises. The possible cause of failure in IR technology is the failure of either the transmitter or the receiver component. And as IR detectors cannot be poisoned, only a physically blocked gas inlet would prevent the sensor from indicating a problem.

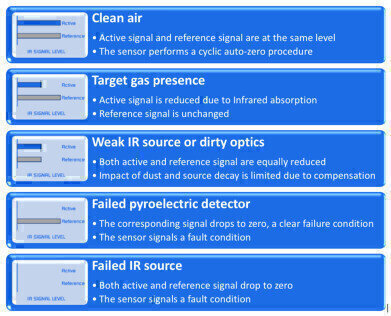

We highlighted below the possible functioning conditions of a typical IR sensor.

As shown in the image, the dual-beam/dual detector redundancy also helps minimizing the effect of signal drift, which allow for calibration cycles of 1 year. N.E.T. sensors, moreover, raise a warning status whenever the IR signal level becomes too weak.

Due to the fail-safe nature of IR gas detection technology and to robust hadware and firmware design, N.E.T.’s range of IRNET, IRNEX and IREF are the only sensors on the market to have reached a certified Safety Integrity Level (SIL) of SIL2 according to EN 50271.

Digital Edition

IET 34.2 March 2024

April 2024

Gas Detection - Biogas batch fermentation system for laboratory use with automatic gas analysis in real time Water/Wastewater - Upcycling sensors for sustainable nature management - Prist...

View all digital editions

Events

Apr 22 2024 Hannover, Germany

Apr 22 2024 Marrakech, Morroco

Apr 23 2024 Kuala Lumpur, Malaysia

Apr 23 2024 Kintex, South Korea

Apr 23 2024 Edmonton, AB, Canada