Water/Wastewater

Interface measurement of oil, emulsions and water in desalters

May 20 2019

Interface measurements in desalters are often regarded as not being very critical, even though every drop of oil, to be refined, passes through the desalter. As refineries try to maximize their margins, so-called opportunity crudes are often used. These crude oils generally contain increased levels of sulphur, oil sands, bitumen, heavy oils and oils with high TAN. This can lead to problems with the proper operation of the desalter. In addition, refineries are increasingly confronted with stricter environmental regulations. The efficient level control of water,emulsions and oil layers in the desalter ensures that salts and minerals are effectively removed and that environmental requirements are met. Therefore, more and more operators are turning to radiometry as a highly reliable and accurate measurement solution for this application.

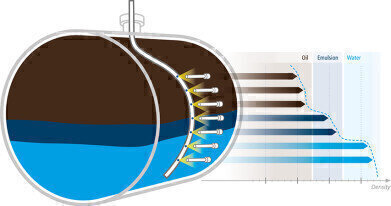

Schematic representation of the Multiphase Level Measurement Emulsion SENS with scintillation detectors mounted outside the vessel.

If a clearly defined interface is formed, different technologies can be used for interface measurement. If a larger emulsion layer is formed, for example, when using “opportunity crudes”, with a significant density gradient change from oil to water, using alternative measurementtechnologies can lead to errors. These cannot determine the height of the emulsion layer and always assume only one separation layer (or interface). This can lead to misinterpretations and the level is either too high or too low.

If the level is too low, hydrocarbons can be entrained with the water/brine effluent and be sent to the waster water treatment plant, where it can cause environmental issues and potential penalties. If the level is too high, it can cause the electrostatic grids to short, therefore potentially allowing water, salts and minerals to be carried over with the crude oil, where water can damage to the distillation columns, salts can cause corrosion issues and fouling of heat exchangers/furnace tubes and minerals such as iron (Fe) can deactivate downstream catalyst.

In addition to controlling water and brine levels, the EmulsionSENS interface measuring system from Berthold Technologies allows you to continuously monitor the gradient change in density to ensure that the water content in the area of the electrostatic grids stays within defined limits, preventing short circuits. In addition, the emulsion layer can be kept continuously at the desired level with the help of an EmulsionSENS, which leads to a significant reduction of the “emulsion breaker chemicals”.

Thus, we reduce the probability of upsets for our customers and maximise throughput in the desalter. This process optimisation saves money in the long term. According to customers and experts, these are savings of $100,000 to $300,000.

Digital Edition

IET 34.2 March 2024

April 2024

Gas Detection - Biogas batch fermentation system for laboratory use with automatic gas analysis in real time Water/Wastewater - Upcycling sensors for sustainable nature management - Prist...

View all digital editions

Events

Apr 22 2024 Hannover, Germany

Apr 22 2024 Marrakech, Morroco

Apr 23 2024 Kuala Lumpur, Malaysia

Apr 23 2024 Kintex, South Korea

Apr 23 2024 Edmonton, AB, Canada