-

Loccioni pressure reducing valve

Loccioni pressure reducing valve -

Loccioni heat exchanger

Loccioni heat exchanger

Water/Wastewater

Heat Exchangers and Pressure Reducers for Steam-Water Sampling and Analysis Systems

Sep 14 2011

Loccioni (Italy) Environment offers complete and customised Steam-Water Sampling and Analysis Systems (SWSAS) and is able to face up the most critical technical issues with its own components.

Heat exchangers are components which are typically used when sample cooling is needed, for both gaseous and liquid sample. They work thanks to a stainless steel cooling coil: the sample is drawn through it and exchanges heat with the cool water which is all around the coil.

Depending on the process conditions of the fluid, Loccioni heat exchangers are dimensioned and manufactured with different coil lengths and geometries, so that the best thermal exchange between sample and water is obtained; they can also be made of special materials on customer’s request.

These components have a very high thermal exchange rate with optimised overall dimensions, and are very resistant against corrosion; their cooling water consumption is low and are easy to be dismounted when a little maintenance is needed.

For the internal engineering of these important components inside SWSAS, Loccioni engineers use a particular calculation procedure, so that the choice of the cooling stages of the SWSAS is optimized and the dimensioning of heat exchangers is the most adequate for each one.

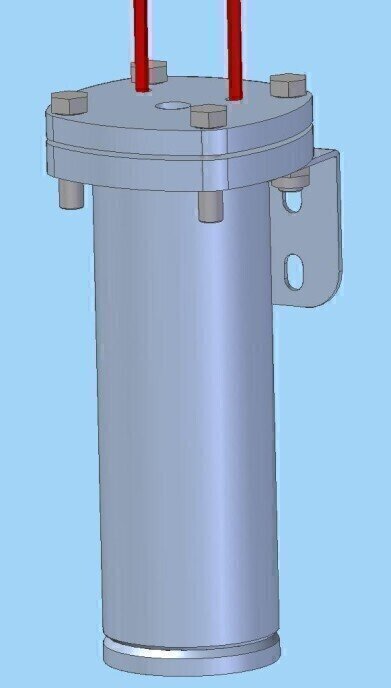

In a lot of cases the sample pressure has to be reduced, so that it always stays inside the admissible range of components and instruments, even during transients of plant functioning: for that Loccioni designs and manufactures variable-capillary pressure reducing valves.

Thanks to this device, the fluid enters the SWSAS with a constant pressure, and this is also independent from variability and fluctuations upstream the valve: this allows to have significant and stable measures at any time instant.

The valve functioning principle is based on a pneumatic feedback between low and high pressure side, with an auxiliary inlet for compressed air used as a reference: the pressure drop across the valve can therefore follow the trend of the upstream pressure thanks to the length change of the inner capillary.

The valve is entirely made in stainless steel and provided with sealing gaskets which guarantee a long time working reliability and a very little maintenance.

Digital Edition

IET 34.2 March 2024

April 2024

Gas Detection - Biogas batch fermentation system for laboratory use with automatic gas analysis in real time Water/Wastewater - Upcycling sensors for sustainable nature management - Prist...

View all digital editions

Events

May 05 2024 Seville, Spain

May 06 2024 Minneapolis, MN, USA

May 13 2024 Munich, Germany

May 15 2024 Lund, Sweden

May 15 2024 Frankurt-am-Main, Germany