Environmental Laboratory

Oxygen Cleanliness & Oil Free Pressure Calibration Services

Nov 12 2019

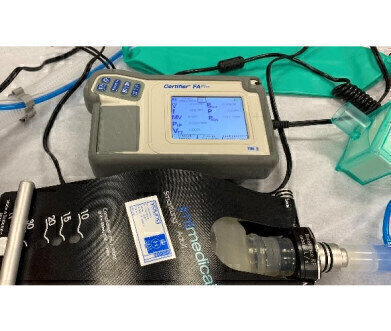

Components, hoses, sensors and instruments utilised in an oxygen environment pose critical safety issues for manufacturers and services providers to ensure all in service items are maintained in a particulate and hydrocarbon free state. Any LOX or GOX system requires an extremely high level of confidence in your laboratory environment, hardware selection and component handling processes way before you delve into the complex processes for component cleaning, extraction and contamination analysis. The Oxygen Cleanroom offers aviation, naval, defence, space and medical sectors a bespoke cleaning and instrument calibration facility for “oil free” oxygen clean systems.

Oxygen Clean Pressure Calibration services for LOX and GOX systems utilised in the medical, marine, aviation, submarine, offshore and space environments. The ISO Class 6 cleanroom provides a dedicated facility for the service and calibration of oxygen clean systems, with an extensive range of cleaning, inspection, analysis and packing solutions. Understanding the bespoke requirements for specific application areas, the cleanroom facility offers all the requirements of gauge inspection, cleaning, calibration, analysis, packing and labelling. The company offers a range of oxygen clean solvents for cleaning, flushing and extraction, with gravimetric, white light, black light, microscopic particle analysis and FTIR spectroscopy. Working to several industry specific standards such as MIL-STD-1330 and the latest highly regarded ASTM G93/G93M-19 standard the company can tailor its process to suit individual needs with cleanliness levels up to Level A component cleanliness. Full system documentation, traceability and certification of results analysis are available for the complete package. Coupled with the recent addition of ISO 17025 UKAS accreditation for oxygen clean calibrations, the lab now offers a complete “oil free” accredited facility for pressure gauges and transducers from MEL, WIKA, King Nutronics, BOC, Budenberg, Stanhope Seta, Ashford and McMaster-Carr.

UKAS fluid flow meter calibration services flowmeters on water as a calibration medium are available on turbine flowmeters, magnetic, coriolis, wedge, differential, ultrasonic and variable area flowmeters with an accredited calibration range from 1 ml/hour to 1000 l/min. Traceable calibrations to ISO 17025:2017 and up to DN150 line size are available up to 4000 l/min. Urgent requirements can be covered on our 24 hr emergency turnaround service upon request.

UKAS ISO 17025 Hydrocarbon Flow Calibration covering 0.5 to 440 l/min on oil for the calibration of turbines, sprung VA, nutating-disk, oval, gear, helical and coriolis flowmeters. Further non-accredited flow calibrations can be completed on ISO 4113, IPA, JET-A1, AVGAS and dielectric fluids. A comprehensive range of aviation fuels and oils are available locally for quick turnaround calibrations.

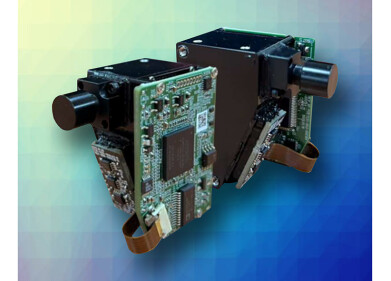

UKAS Airflow Calibration for volume and mass flow meters, rotameter (VA), MFC, MFM, laminar, vortex, turbine, thermal meters. The UKAS accredited laboratory ranges from 1 cc/min to 1250 litres/sec, enabling the calibration of the smallest leaks to 300 mm insertion vortex and laminar flowmeters. Gas calibration lines are available for traceable calibrations on a range inert gas with high flow atmospheric air for balometers and fume hood flow sensors, with further test rigs the calibration of air sampling systems utilised in the environmental sectors.

UKAS Air Velocity Calibration for ultrasonic, thermal, vane and rotating cup anemometers, along with high accuracy uniform flow profiling for pitot tube, isokinetic probes and CTA’s covering 0.05 to 80 m/s. The ISO 17025 accredited wind tunnels allow for complete air velocity profiling using 2D laser doppler anemometry and the determination and characterisation of anemometer blockage corrections.

Digital Edition

IET 34.2 March 2024

April 2024

Gas Detection - Biogas batch fermentation system for laboratory use with automatic gas analysis in real time Water/Wastewater - Upcycling sensors for sustainable nature management - Prist...

View all digital editions

Events

Apr 30 2024 Melbourne, Australia

Apr 30 2024 Birmingham, UK

May 03 2024 Seoul, South Korea

May 05 2024 Seville, Spain

May 06 2024 Minneapolis, MN, USA