-

COAGULANT DOSE RATE VERSUS DOC REMOVAL DIAGRAM

COAGULANT DOSE RATE VERSUS DOC REMOVAL DIAGRAM -

What is coagulation

What is coagulation -

UV-UV-Vis compensated and uncompensated spectra

UV-UV-Vis compensated and uncompensated spectra

Water/Wastewater

What is coagulation and how to control it using online UV-VIS SPECTROMETERS

Oct 10 2011

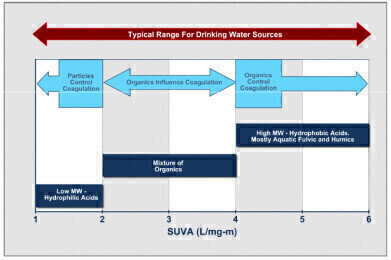

Achieving reliable automatic coagulation control is something many water companies struggle to maintain in highly variable (flashy) catchment areas. These areas can be at one time or another; typically low in particulates with a moderate to high natural organic matter (NOM) content & vice versa. The water quality can change very rapidly following rainfall events. This upsets previous steady state conditions, and can often reverse the balance and alter the coagulant demand parameters (see SUVA Raw Water diagram left). Such water quality “events” present a challenge to conventional water treatment processes and coagulation control in particular. Recent advances in instrumentation have enabled water suppliers to dispense with single wavelength UV254 monitors, or streaming current/Zeta potential controllers, and instead install UV-VIS spectrophotometers for continuous online water quality monitoring. These modern UV-Vis instruments can be used to measure the quantity of NOM and infer changes in the characteristics of NOM during water quality events. This knowledge can be used to optimise conventional treatment plants for NOM removal in the most cost effective manner, without a deleterious effect on particulate removal by regulating coagulant dose rate. It is this capability that defines successful coagulation control. More>>

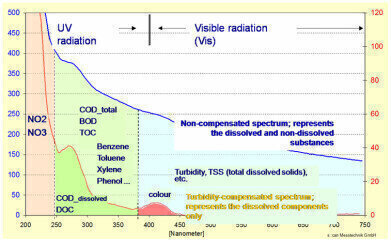

UV-VIS & NOM Characterisation & SUVA Calculation

In order to achieve good coagulation performance from any automatic dosing system, a commercially available coagulant with characteristics to match site conditions (and pocket) is usually selected. In many cases this will often be what is widely referred to as Alum or alternatively Ferric, or a combination of one or the other depending on seasonal changes. Some water treatment works switch from say Alum to Ferric during summer conditions as the water matrix changes requiring different performance characteristics from the coagulant. Coagulation control is therefore a matter of controlling the optimal dose rate of the coagulant such that plant compliance is maintained in a robust, reliable and cost effective manner for different types of coagulant across all seasonal conditions. To ensure this happens from a UV-Vis measurement perspective, we are required to compensate the raw water matrix for suspended solids, and then divide the analysis into “dissolved compounds” and particulate matter. These impact on coagulant demand, often in a diametrically opposed manner. This is not as easy as it sounds. For example; “true” colour is the dissolved colour of a liquid with solids removed (filtered), “apparent” colour (that which the human eye sees) is the combined colour resulting from both coloured dissolved, particulate & colloidal matter. Any reliable system must be able to distinguish and characterise these variations such that the correct dose rate is delivered and optimal DOC removal is achieved. S::CAN’s submersible spectrometer: the “Spectrolyser” achieves this online within seconds. The Spectrolyser combined with the Compass olgarithms stored on the S::CAN analyser system are the key to reliable automatic coagulation control. Streaming current or Zeta potential systems are unable to characterise raw water in this way and therefore suffer poor control when sudden flashy environmental conditions present themselves at the water treatment works inlet, ironically, just when a reactive and responsive control system is needed!

UV-UV-Vis compensated and uncompensated spectra

Historically, the measurement of UV absorbance at a single wavelength of UV 254 nm is a widely accepted surrogate for natural organic matter (NOM). However, in order to characterise NOM, additional measurements need to be made. Measuring the dissolved organic carbon content (DOC) enables the specific UV absorbance, or SUVA254, of the water to be calculated. SUVA254 has been shown to correlate with the apparent molecular weight (AMW) of aquatic NOM. As the AMW of NOM increases, the SUVA254 value tends to increase. A higher SUVA254 value suggests that the NOM present is more hydrophobic in nature and therefore more likely to influence and be removed by coagulation and subsequent solids separation. The diagram below attempts to illustrate the relationship.

S::CAN Submersible Spectrometer & Compass automatic coagulant control software

The company S::can produces a UV-VIS spectrophotometer for continuous online water quality monitoring. This instrument can be used to measure the quantity of NOM and infer changes in the characteristics of NOM during water quality events. This data, along with standard turbidity measurement, is used by the Com::pass software system to predict the coagulant dose required to achieve treatment aims. This form of feed-forward coagulant dose control has been successfully applied on-line at numerous plants worldwide. S::CAN UV-VIS spectrometers measure light absorbance across a range of wavelengths (e.g. 200-750nm) and are generally accepted to improve the robustness and accuracy of the NOM measurement when compared to a single wavelength UV254 sensor based monitoring system. Measurement across multiple wavelengths provides an absorption fingerprint profile or “spectra” from which other parameters can be derived, such as a DOC equivalent (DOCeq). Recent developments in instrument technology have resulted in the availability of UV-VIS spectrophotometers capable of online measurement, giving the user field based, and real time UV-VIS spectral data. This in turn has resulted in predictive, online, real time and reliable coagulation control becoming a very real possibility even under challenging and changeable environmental conditions.

Automatic Coagulation Control

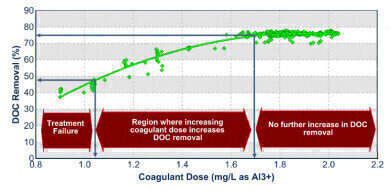

DOC removal tends to follow the course predicted by the graph below. Extreme ends of the scale result in treatment failure, or excessive coagulant dosing fails to provide any additional DOC removal despite increased monetary spend. It can be seen in the example below that ideally the coagulant dose rate would fall between approximately 1.1 – 1.7mg/l. 1.1 mg/l being the most economical dose rate of coagulant that could be used as a set point in order to maintain plant compliance with a degree of safety built in. Higher dose rates approaching 1.7mg/l provide maximum DOC removal and reduced THM production potential.

Compass: a tried and tested UV-Vis based automatic coagulation controls system.

Compass is a commercially available coagulant control system as described above. Compass is available from Process Measurement & Analysis Ltd. PMA have worked with H2Hope and DCM Process Controls to successfully combine the S::CAN submersible spectrometer into a robust and reliable coagulation control system for the UK potable water market (www.processmeasurement.uk.com). We welcome enquiries from any Municipal UK water company with a further interest in automatic coagulation control systems.

Digital Edition

IET 34.2 March 2024

April 2024

Gas Detection - Biogas batch fermentation system for laboratory use with automatic gas analysis in real time Water/Wastewater - Upcycling sensors for sustainable nature management - Prist...

View all digital editions

Events

May 05 2024 Seville, Spain

May 06 2024 Minneapolis, MN, USA

May 13 2024 Munich, Germany

May 15 2024 Lund, Sweden

May 15 2024 Frankurt-am-Main, Germany