Water/Wastewater

New Nano-Engineered Laboratory Based Optical Dissolved Oxygen System Launched

Feb 02 2011

“Optical technology replaces the classic Galvanic method of dissolved oxygen measurement and offers many advantages.”

Aquaread Ltd is the UK’s only designer and manufacturer of multiparameter water quality testing instruments. The company originally launched their GPS Aquameter in 2008 which measures up to 20 different parameters at once, including pH, dissolved oxygen, turbidity, conductivity and records GPS coordinates – an innovation in field measurement.

Following the success of this instrument, Aquaread Ltd have launched a new electrode designed specifically for use in the laboratory, which measures dissolved oxygen using optical technology. Optical technology replaces the classic Galvanic method of dissolved oxygen measurement and offers many advantages. The Galvanic method features a delicate oxygen permeable membrane. During measurement oxygen must pass through the membrane and react with the electrolyte solution within the membrane cap. This creates a current proportional to the amount of oxygen present.

The Galvanic method however has the following drawbacks; a constant flow of liquid is required to make readings because the oxygen is consumed as it passes through the membrane, the membrane itself is delicate and must be replaced every 1-2 months, the cap that features the membrane must be filled with electrolyte solution and the membrane is prone to cross sensitivity to sulphides, sulphates, chloride, carbon dioxide or ammonia.

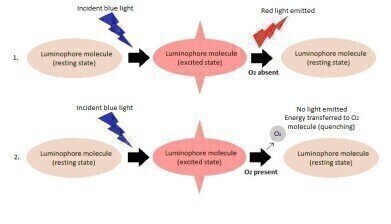

The new optical technology overcomes all these issues. The permeable membrane is replaced with a gas permeable sheet called a luminophore, which is a substance that can be exited by light. The luminophore is exited by blue light and dependant on the amount of oxygen present, varying levels of red light will be emitted (see Figure 1 for a flow diagram example). By measuring the delay of the returned red light with respect to the blue excitation, the level of dissolved oxygen present can be determined.

The Optical electrode has many advantages over the Galvanic method, no flow of liquid is required as oxygen is not consumed across the membrane, the user replaceable electrode cap requires replacement every 1-2 years, a vast improvement on 1-2 months, plus it requires no electrolyte solution. Thanks to the above points this optical electrode is almost maintenance free and will out-last any Galvanic cell. This technology has no cross sensitivity to sulphides, sulphates, chloride, carbon dioxide or ammonia often found in water. In addition, the stable nature of the luminophore means the need for calibration is much less frequent.

The life of the luminophore is maximised thanks to some clever software. Every time the luminophore is exited, its ability to emit light is slightly reduced. But by adjusting the intensity of blue light used to excite the luminophore to an absolute minimum, it is possible to reduce unnecessary degradation. This automatic adjustment helps to give the cap a very long life of up to 2 years, which way surpasses the life of a Galvanic membrane.

The designers at Aquaread Ltd describe the technology as ‘nano engineered’ due to the small size of the sensor module. The sensor is housed in a resin filled, aluminium body that measures just 8mm diameter, making it more than 5 times smaller than some of the other optical instruments on the market. The sensor module not only houses all the Optics for measurement, it also contains a temperature sensor to allow for automatic temperature compensation.

Fitting all this technology into such a small space has enabled Aquaread to produce an electrode specifically designed for lab applications, such as oxygen measurement in biological oxygen demand (BOD) experiments.

The AquaLab system has the following Lab specific advantages; slim diameter to fit in 12mm BOD bottles, it is GLP compliant, all calibration data stored within the probe not the meter. The meter features a built in air pressure sensor, automatic compensation for temperature, air pressure and salinity (manual salinity input). The meter comes complete with magnetic support stand for better viewing angle, intuitive and easy to use operating system and very simple calibration. It has a 3000 data point capacity and allows automatic or manual data logging. The system is provided with OxiLink software CD featuring various export options such as a detailed report or an excel file and for data management and storage.

The AquaLab system provides an update to old technology by offering significant improvements in terms of longevity of the cap life, no stirring requirement, low maintenance and no cross sensitivity. In addition to these improvements the technology is presented in an elegantly small electrode, designed specifically for use in the laboratory in applications such measuring BOD in small 12mm bottles.

Digital Edition

AET 28.3 September 2024

September 2024

Business News - ENVEA announces acquisition of APAQ Group - SICK and Endress+Hauser sign strategic partnership - Efforts to curb gas flaring intensify amid environmental concerns Air Monito...

View all digital editions

Events

WEATHER • CLIMATE • WATER / EARTH OBSERVATIONS / GREEN ECONOMY

Oct 29 2024 St. Petersburg, Russia

Oct 30 2024 Hong Kong

Nov 05 2024 Toronto, Canada

Nov 05 2024 Rimini, Italy

Nov 06 2024 Ho Chi Minh City, Vietnam

.jpg)