Water/Wastewater

Revolutionary three-diaphragm liquid pump delivers high flow rates at low pulsation.

Jul 03 2019

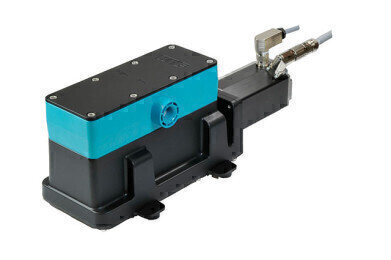

KNF’s new FK 1100 diaphragm liquid pump is one of the most advanced solutions on the market for transferring liquids at high flow rates gently with low pulsation. This is required as for example in industrial inkjet, food processing or cooling circuit applications. The robust, adjustable pump is offered in a variety of materials, and comes in food-safe and chemically resistant versions.

The recently released FK 1100 has a flow rate of up to 12 liters per minute, doubling KNF’s previous maximum for liquid diaphragm pumps. The pump has only one inlet and one outlet, despite having three diaphragms working inside. These are offset at 120° to each other while connected in parallel, which results in very low pulsation and minimal shear forces. Intensive testing has proven that the pump easily achieves pulsation values below 200 mbar at the inlet and outlet. This permits the new pump to convey liquid very gently and to protect fragile elements of the media.

The FK 1100 is anything but fragile. It has a highly durable and robust design with a die-cast aluminum housing and high-torque motors that provide continuous operation with up to 6 bar back pressure, even at this high pressure, the pump delivers an impressive 8 l/min.

Further advantages of diaphragm technology include the use of elastomer diaphragms, which remove the risk of contaminating the media in the pump and allow almost any type of liquid to be conveyed, including corrosives. The pumps are self-priming with 4.5 mH2O suction height, and able to run dry which reduces the need for additional equipment.

Versions are available in a variety of carefully selected materials, for example with NSF certification for food applications, or elastomers with higher chemical resistance. Customers can also choose between different drives, such as brushless DC or single-phase AC motors. The speed of the brushless DC motor can be controlled using analogue or digital PWM signals, permitting lower flow rates if necessary.

Digital Edition

IET 34.2 March 2024

April 2024

Gas Detection - Biogas batch fermentation system for laboratory use with automatic gas analysis in real time Water/Wastewater - Upcycling sensors for sustainable nature management - Prist...

View all digital editions

Events

Apr 30 2024 Melbourne, Australia

Apr 30 2024 Birmingham, UK

May 03 2024 Seoul, South Korea

May 05 2024 Seville, Spain

May 06 2024 Minneapolis, MN, USA