-

Air Liquide’s upgrading vessel at the Doncaster site.

Air Liquide’s upgrading vessel at the Doncaster site. -

The Doncaster site where the upgrading takes place.

The Doncaster site where the upgrading takes place. -

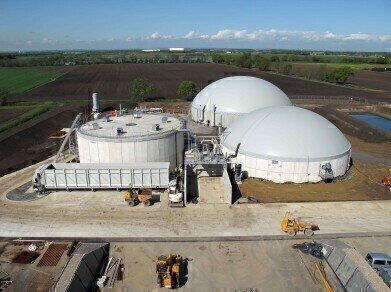

Digester at the Norwich site.

Digester at the Norwich site. -

Geotech’s portable gas analyser is used globally.

Geotech’s portable gas analyser is used globally.

Portable/Field Testing

Biogas monitoring for upgraded biomethane

Feb 11 2015

By working with a range of partners worldwide, Geotech (UK) is involved in a range of projects at the cutting edge of biogas production and processing. The recent landmark deal agreed between Marks & Spencer (M&S) and Future Biogas, a major biogas plant operator, is for the purchase of biomethane certificates.

The deal sees M&S purchase 35,000 Mega-Watt hours (Mwh) of certificates, which represent the 'bio' element of biomethane produced at anaerobic digestion (AD) plants. The certificates will help to generate the equivalent amount of energy to heat 15 M&S Simply Food stores all year round, reducing the retailer's carbon footprint by more than 6,400 tonnes.

Geotech has worked with Future Biogas to supply biogas monitoring equipment for a number of projects. The company uses Geotech’s GA3000 PLUS fixed gas analyser and their portable biogas analyser, the BIOGAS 5000 to measure and monitor the gas being produced on site. Whilst the fundamental requirements of reliable equipment for measuring the composition of hot, corrosive biogas remain the same across projects, there can be additional demands.

Future Biogas produces biomethane and electricity from biomass in a number of Anaerobic Digestion facilities across the country. Geotech’s monitoring equipment is used to monitor the health of the fermentation and also check the condition of the biogas entering the gas upgrade unit to prevent damage to the upgrading membranes. Typically the methane (CH4) yield, which can vary depending on the feedstock used, is the gas most closely monitored. Methane is measured to indicate the revenue being generated and that the process is optimised. Small deviations in methane levels can be significant so reliable and accurate equipment is critical. A fast, local response is also particularly important for the fixed monitoring system, which may be linked into site alarms and without which the plant cannot fully function.

Other gases monitored include oxygen (O2) and hydrogen sulphide (H2S). An increase in oxygen, which can seriously damage expensive CHP engines, can be caused by a leak of air into the system. H2S is generated, to different extents, by anaerobic digestion of different feedstocks and is also a major threat to efficient running of the engines.

M&S is the first UK retailer to buy biomethane to use in this way. Biomethane gas is 50% more carbon efficient than average gas supplies and is generated by AD fuelled by farm waste. The £8m Vulcan AD plant near Doncaster will use non-commercial crops from farms across Yorkshire and the North East. Future Biogas is working on introducing sustainable break cropping feedstocks such as wildflower mixes, sunflower and ryegrass mixes.

The Biomethane Certification Scheme (BMCS) that M&S has signed up for is an independent certification scheme run by Green Gas Trading (GGT), a private limited company, which hopes to broaden the market and further facilitate links between green gas producers and buyers. The scheme is backed by the Anaerobic Digestion & Biogas Association (ADBA), as well as other operators using Geotech’s biogas monitoring equipment, such as Tamar Energy.

Digital Edition

IET 34.2 March 2024

April 2024

Gas Detection - Biogas batch fermentation system for laboratory use with automatic gas analysis in real time Water/Wastewater - Upcycling sensors for sustainable nature management - Prist...

View all digital editions

Events

Apr 30 2024 Melbourne, Australia

Apr 30 2024 Birmingham, UK

May 03 2024 Seoul, South Korea

May 05 2024 Seville, Spain

May 06 2024 Minneapolis, MN, USA

-QED-Image.jpg)