Gas Detection

New City Technology hydride sensors support next generation digital and green technologies

Dec 07 2011

The global semiconductor industry, and the emerging photovoltaic industry, which is rapidly developing in response to the pressure for carbon reduction in energy production, has seen hydride gas usage increase dramatically in the last five years.

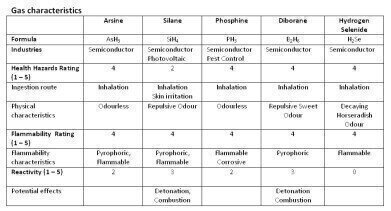

Hydride gases such as arsine, silane, phosphine, diborane and hydrogen selenide now play a critical part in semiconductor and photovoltaic material manufacturing, but their highly toxic, corrosive and explosive nature requires extensive safety precautions to ensure safe work environments and properly functioning processes.

The main gases used in the manufacturing processes all exhibit potentially life-threatening characteristics, even in relatively low concentrations. Their specific characteristics are shown in the table below. In addition, they are all extremely flammable with silane and diborane potentially explosive at room temperatures. Stringent monitoring for both life safety and plant protection reasons is therefore essential.

In addition to their life-threatening properties, the hazardous nature of the gases is underlined by their inclusion in NFPA 704, a well-known standard maintained by the US-based NFPA, the National Fire Protection Association. It defines the "fire diamond" used by emergency personnel to quickly and easily identify the risks posed by nearby hazardous materials. The standard helps determine what specialty equipment should be used, which procedures should be followed and the precautions that should be taken during the initial stages of an emergency response.

To provide the necessary protection, fixed gas monitoring systems are installed in critical areas throughout the plant. It is estimated that electrochemical hydride detectors account for around 60% of the market and the trend continues upwards.

During the last twenty years, City Technology has built a worldwide reputation with its state of the art Sensoric range of exotic gas sensors. In particular, the hydride sensors, which are used throughout the world in semiconductor manufacturing plants, make a critical contribution to the operation of the plant and the protection of the facility infrastructure and the safety of the workforce. The Sensoric sensors guarantee the safe manufacture of the technology that underpins the digital world that we take so much for granted today through an outstanding track record for performance, quality and reliability. The Sensoric product attributes, combined with the outstanding service, support and technical backup from City, have made the Sensoric hydride sensors the unit of choice for instrument manufacturers. Sensoric hydride sensors are the undisputed market leader, with a large installed base in this critically important specialised sector.

Although relatively small compared to semiconductor manufacturing, the carbon-free energy generation sector is another important area that used exotic gas sensing. The volume manufacturing of photovoltaic converters, which generate pollution-free electricity directly from sunlight, is rapidly increasing to meet the demand for clean energy generation. Many new production facilities are coming on-stream, ramping up the need for high reliability safety and monitoring systems to protect people and plant. The latest generation of Sensoric’s hydride sensors, which provide significantly improved performance over the generation they replace, are already playing a critical part in supporting this essential new industry.

To meet users’ requirements for longer operating life, increased responsiveness and greater stability in the high flow, high temperature environment in which they are typically used, the new generation of hydride gas sensors utilise innovative ionic liquid electrolyte to provide outstanding performance. Hydride gas sensors and detectors must exhibit high stability throughout the equipment’s working life and function effectively in continuous sample flow and high temperature conditions. The consequences of false alarms and process downtime are very costly in continuous manufacturing processes such as wafer fabrication, and manufacturers have constantly sought the most reliable instrumentation to protect their product integrity, facilities and employees.

The new designs are enhanced versions of existing arsine, silane and phosphine sensors with an ionic liquid electrolyte in place of the original gel; two new sensors that are characterised to diborane and hydrogen selenide are also introduced.

Ionic liquids

Ionic liquids are salts that are liquid over a wide temperature range, including room temperature, and typically contain at least one organic ion. They have been known for over a century, but only in the last decade have their superior qualities been appreciated and used in material applications. The patented ionic liquid combination possesses excellent thermal stability and no measurable vapour pressure. The properties of the electrolyte result in more stable performance in the high flow, low humidity and high temperature conditions that are typical to semiconductor applications.

Since ionic liquids have a very low vapour pressure, they are far less susceptible to drying out over time than traditional gel electrolyte systems, a significant factor for applications in the semiconductor industry, where the detectors are typically mounted in ducts monitoring a constant flow of hot dry gas. The stability of the new ionic liquid electrolyte sensors, both over time and in aggressive atmospheres where temperature and humidity can rapidly change, is greatly enhanced.

For applications where hydrogen sulfide (H2S) is present or for instruments that are calibrated with H2S gas, a filtered version of the ionic liquid based hydride sensors are also available.

Operating life

In previous gel-based arsine, silane and phosphine sensors, operational life was restricted because of the tendency for the gel to dry out. The liquid electrolyte replacements overcome this problem, reducing the lifetime cost of ownership.

Environmental operating envelope

The new sensors offer better output level stability, responsiveness and overall performance in the aggressive atmospheres in which they are required to work. The output level from the sensors is fundamentally stable when exposed to the wide variations in operating temperature, relative humidity and gas flow rates that will be encountered during normal operation; in particular, the sensors perform well in the typical high temperature, low humidity and high gas flow rate environment that is characteristic in a semiconductor foundry.

Cross-contamination sensitivity

Cross sensitivities are extremely good, with no significant response to a wide range of gases that may be present in the monitored environment. Versions of the arsine and phosphine sensors fitted with a 200ppm hour capacity H2S filter are available on a customer by customer basis if required.

The new sensors have been extensively tested for exposure to IPA, isopropyl alcohol, which is widely used as a cleaning agent, and there is no effect on sensor output level during exposure to the cleanser.

Hydride gases in the semiconductor industry are typically diluted with hydrogen when fed to epitaxial reactors. Cross sensitivity tests on new hydride sensors show zero cross sensitivity to hydrogen, eliminating the likelihood of false alarms.

Conclusions

The semiconductor and photovoltaic cell manufacturing industries are key enabling technologies for both the developed and developing worlds. In addition to providing the foundation of today’s high technology digital infrastructures, the increased use of carbon-free power generation, on a micro and macro scale is critical to reducing the environmental impact of human activity.

In a small but critical way, the latest developments of the Sensoric range of sensors play their part in improving the efficiency of the core manufacturing technologies. By delivering improvements in the performance of existing arsine and silane sensors, and introducing sensors for a further two widely-used hydrides used in the semiconductor and increasingly; the photovoltaic manufacturing industries, these industry become safer places to work.

With a commitment to continuous improvements in quality and sensors that detector more exotic gases than anyone else, the introduction of these new toxic gas sensor designs further reinforces City Technology’s position as the world’s leading, and most innovative manufacturer of exotic gas sensors for life safety and facility protection applications.

Digital Edition

IET 34.2 March 2024

April 2024

Gas Detection - Biogas batch fermentation system for laboratory use with automatic gas analysis in real time Water/Wastewater - Upcycling sensors for sustainable nature management - Prist...

View all digital editions

Events

Apr 30 2024 Melbourne, Australia

Apr 30 2024 Birmingham, UK

May 03 2024 Seoul, South Korea

May 05 2024 Seville, Spain

May 06 2024 Minneapolis, MN, USA