Environmental Laboratory

Analytical challenges in mercury determination

Apr 18 2019

The analytical challenges presented by measuring mercury using techniques like cold vapor atomic absorption/atomic fluorescence (CVAA/AF), or Inductively Coupled Plasma Mass Spectrometry (ICP-MS) are well recognised. The inherent problem lies in the fact that all these techniques are solution-based which means that if the sample is not a liquid it has to be digested before it is introduced to the instrument. Because of the high volatility of mercury, this can lead to loss of analyte and poor recoveries if the sample is not digested correctly. In addition, even if the sample is a liquid, mercury is notorious for its memory effects, particularly using techniques such as ICP-OES or ICP-MS because it can stick to the walls of the sample container as well as surfaces of the sample introduction system. The bottom line is when carrying out mercury measurements at low levels, great care must be taken to ensure the data generated is representative of the mercury in the original sample.

Direct Mercury Analysis

One of the most widely accepted ways around these limitations is to carry out the measurement by direct mercury analysis, which is a technique used for the determination of total mercury directly in solid, liquid and gas samples, using the principle of thermal decomposition, amalgamation and atomic absorption. In this approach, a decomposition furnace is used to release mercury vapor instead of the chemical reduction step used in traditional liquid-based analysers. Both solid and liquid matrices can be loaded onto the instrument’s autosampler and analysed without acid digestion or sample preparation prior to analysis. Because this approach does not require the conversion of mercury to mercuric ions, lengthy sample pretreatment steps are unnecessary. As a result, there is no need for reagents such as highly corrosive acids, strong oxidising agents or reducing chemicals, which means, no hazardous waste to be disposed of. Direct mercury analysis is a well-established analytical technique used by the environmental, biological, clinical, food, industrial and academic communities that has been approved by testing/standards organisations such as the EPA in method 7473 and the ASTM using Method D6722.

Learn more about DMA-80 evo

The benefits of the new DMA-80 evo

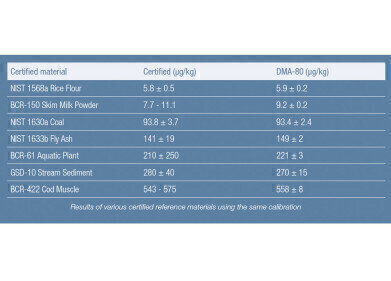

For the very first time, the benefits of double beam technology have now been incorporated into the design of a direct mercury analyser with the Milestone DMA-80 evo. This significantly increases the signal-to-noise ratio, which greatly improves the stability of the signal, resulting in a lower limit of quantification and enabling more accurate and precise mercury determinations even at the low-ppt level.

The DMA-80 evo offers a significant enhancement in productivity and efficiency over ICP-MS and cold vapor systems. Not only do these techniques require labor intensive and time-consuming sample preparations steps, which can lead to mercury losses, but also all the hazardous waste chemicals and solutions must be disposed of in a safe manner.

The enhancement in productivity of the DMA-80 evo over CVAA is demonstrated here. Total savings of almost $500 per day or $10,000 per month.

Milestone are and have been the benchmark for direct mercury determination in most industries: environmental, food, energy, cement, cosmetics, agriculture, mining, and petrochemical. With thousands of DMA-80s installed in over 80 countries, Milestone has a wealth of experience and knowledge regarding direct mercury determination, ensuring your lab state-of-the-art technology and premium customer support.

Discover our valuable resources

Digital Edition

IET 34.2 March 2024

April 2024

Gas Detection - Biogas batch fermentation system for laboratory use with automatic gas analysis in real time Water/Wastewater - Upcycling sensors for sustainable nature management - Prist...

View all digital editions

Events

Apr 30 2024 Melbourne, Australia

Apr 30 2024 Birmingham, UK

May 03 2024 Seoul, South Korea

May 05 2024 Seville, Spain

May 06 2024 Minneapolis, MN, USA