Air Monitoring

New Revolutionary Monitoring System Launched

Feb 29 2008

companies in the gas turbine industry improve efficiency and reduce downtime.

The Epsilon Gas Turbine inlet filter monitor measures particulates at sub ambient concentration levels in large gas turbine power plant inlet ducts. It is the only instrument in the world that is able to provide full duct coverage on this type of application, along with a spatial map of the distribution of the particulate within the duct itself.

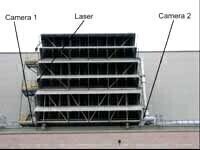

This innovative instrument has been designed by Etr-Unidata to monitor

the real time performance of large banks of inlet filters that protect the gas turbine compressor blades. The filter banks, which can be up to six storeys high, contain several hundred filters all of which have to be checked manually by the operator in the event of breakdown or at the time of programmed maintenance.

The challenge for the Epsilon Systemwas to monitor very low sub-ambient

particles concentration levels that are typically associated with inlet air down-stream of a filter bank, and do so over the entire filter bank. The system would of necessity provide a high degree of spatial resolution, or particle mapping, as well.

With online profiling of the entire cross-section of the filter, both the rate and the location of deterioration can be monitored continuously by the Epsilon system. Early warning of deterioration means down-time decisions can be made solely on the basis of process monitoring. If a decision to shut down is warranted, the specific location where repair or replacement is required will already be known, and the duration of down-time minimized. Overall filter bank efficiency can also be monitored over time.

Epsilon employs advanced digital imaging processing combined with sophisticated signal processing to produce detailed cross-sectional images of an entire duct/stack, from thousands of separate images generated with Epsilon’s patented laser based scanning technology.

The Epsilon system has been three years in the making, culminating in extensive testing at Keadby Power Station in Lincolnshire. Additionally the system will be trialled at E.ON UK’s newest Combined Cycle Gas Turbine site at Enfield in Middlesex.

Cameron Stathers, UK Sales Manager for Etr-Unidata says: “The Epsilon instrument will bring significant benefits to gas turbine power station operators. For the first time they will have real-time information on how the individual inline filters are performing and will be able to make valued judgements on the build up of particulates on the compressor blades. We have already had interest from several major gas turbine power station operators in the system.â€

Digital Edition

AET 28.2 April/May 2024

May 2024

Business News - Teledyne Marine expands with the acquisition of Valeport - Signal partners with gas analysis experts in Korea Air Monitoring - Continuous Fine Particulate Emission Monitor...

View all digital editions

Events

Jul 30 2024 Jakarta, Indonesia

China Energy Summit & Exhibition

Jul 31 2024 Beijing, China

2024 Beijing International Coal & Mining Exhibition

Aug 07 2024 Beijing, China

IWA World Water Congress & Exhibition

Aug 11 2024 Toronto, Canada

Aug 25 2024 Stockholm, Sweden and online

.jpg)