Air Monitoring

Dust Monitor for Wet Gases

Mar 31 2008

These are no suitable applications for in-situ dust monitoring because all optical monitors would recognize droplets and dust in the same way and the droplets would invalidate any dust measurement. A practical way to solve this problemis to extract the gas and to vaporize the droplets.

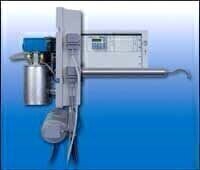

The D-R 820 F by Durag (Germany) is designed to measure dust concentrations in saturated flue gas containing water droplets using the forward-scattered light measuring principle. Any droplets are vaporized and thus cannot falsify the result of themeasurement.

The gas is withdrawn via a special sampling probe by means of an injector supplied by a blower. The representative measuring gas sample is extracted from the flue gas duct via a probe and conditioned before it is supplied to a scattered-light cell.

In the front part of the probe the sampled gas is mixed with clean, tempered dilution air in a defined way. Thus, it is possible to measure dust concentrations also with difficult exhaust conditions (wet gas, sticky constituents).

The D-R 820 F then uses the transmitter/receiver unit to measure the scattered-light intensity in the test cell as a measure of the dust concentration.

Operating principle: The sampling probe and the scattered-light cell form a construction unit. According to the respective measuring

task the quantity of dilution air and the measuring gas temperature are adjusted in such a way that water drops are eliminated surely and

the measuring signal is only a result of the solid particles.

The measuring gas flow is sucked with the help of an injector through the measuring cell, where flow monitoring by the measurement of the differential pressure over the measuring cell takes place. The D-R 820 F device operates according to the principle of forward scattering. The gas is measured with a standard scattered light instrument in a special measuring cell, similar to those used for In-situ purposes. The concentrated and modulated light of a laser diode penetrates the measuring cell. The forward-scattered light largely reflected from dust particles is measured and assessed. Following this, the test gas is returned to the duct.

A bypass valve is used in conjunction with the probe nozzle diameter to adjust the sampling rate to a slightly over-isokinetic sampling

condition at full-load unit operation.

Applications: Measuring dust concentrations, e.g. in saturated gas downstream of desulfurization plants; downstream of wet scrubbing plants, e.g. in waste incinerators; in wet exhaust gas from industrial processes or in applications with sticky types of dust.

The sample gas is forwarded via the ejector by means of a blower unit that also supplies the transmitter/ receiver unit with purge air

for keeping the optical boundary surfaces clean.

Applications are to be found in e.g.: chip board production, urea industry, insulating material production, behind wet scrubber and

similar applications Frame with blowers and evaluation unit: Two blowers for the operation of the injector and for the production of the dilution air as well as the electronic evaluation unit are installed together on a frame.

Benefit for the user of the D-R 820 F: The D-R 820 F offers a set of advantages to the user. Apart from the possibility of the application

under the most diverse and complicated basic conditions it distinguishes above all through its: extraordinarily compact design, no

necessity for a complex gas sampling and very small maintenance requirement.

All necessary settings can be conveniently made using the integrated keyboard and the menu-guided display. External setting aids

or a laptop are not required.

The relative extendedmeasuring uncertainty QAL1, at 6 %, is well below the permitted limit of 30% of the daily limit value. The preventive

maintenance interval for the device is 2 months, or 6 months in managed systems that are subject to regular inspection. The lowest dust

measuring range is 0-15mg/m3 at an absolute moisture of up to 40%.

Digital Edition

AET 28.2 April/May 2024

May 2024

Business News - Teledyne Marine expands with the acquisition of Valeport - Signal partners with gas analysis experts in Korea Air Monitoring - Continuous Fine Particulate Emission Monitor...

View all digital editions

Events

Jul 30 2024 Jakarta, Indonesia

China Energy Summit & Exhibition

Jul 31 2024 Beijing, China

2024 Beijing International Coal & Mining Exhibition

Aug 07 2024 Beijing, China

IWA World Water Congress & Exhibition

Aug 11 2024 Toronto, Canada

Aug 25 2024 Stockholm, Sweden and online

.jpg)