Environmental Laboratory

Selecting the Best Technique for Mercury Measurement

Mar 17 2016

Increasing demand for better control and monitoring to mitigate or limit mercury released into the environment has necessitated the development of several highly-sensitive mercury analysis techniques. For many labs, particularly those conducting environmental analysis, the chosen technique is driven by the regulatory method required. For others, sample matrix (i.e. solid or a liquid), required detection limits, sample digestion vs. direct analysis and budgetary constraints are all important considerations. A brief summary of the primary techniques for mercury detection is listed below.

Cold Vapour Atomic Absorption Spectroscopy (CVAAS)

Liquid samples are most likely best served by the chemical reduction techniques of CVAAS and CVAFS. In many parts of the world, reduction of aqueous samples and mercury determination by CVAAS is the commonly used technique, providing trace to ultra-trace detection limits of ng/L.

Typically CVAAS instruments use a peristaltic pump to transport sample and stannous chloride to a Gas Liquid Separator (GLS). Gas is introduced to the liquid mixture and mercury vapour is released, dried and sent to an atomic absorption optical cell. Because mercury absorbs light at 253.7 nm in logarithmic proportion to its actual concentration in the sample, a detector linked to software can then determine mercury content.

Cold Vapour Atomic Fluorescence Spectroscopy (CVAFS)

CVAFS-based mercury analysers typically have ultra-trace ng/L detection limits, a much wider dynamic range than CVAAS, typically four orders of magnitude for CVAFS versus three to four for CVAAS, and gold amalgamation systems for pre-concentration of mercury before detection.

The process of sample introduction up to the release of mercury vapor is similar to CVAAS, although chemical preparation prior to analysis may be quite different. The mercury vapour can then be pre-concentrated using gold amalgamation, or sent directly to the fluorescence detector. The mercury vapour absorbs light at 253.7 nm creating fluorescent light at the same wavelength. The intensity of the fluorescent light is directly proportional to the concentration of mercury in the sample.

Direct Analysis by Thermal Decomposition

Thermal decomposition combusts a sample in native form, eliminating the sample digestion pretreatment required by both CVAAS and CVAFS techniques. While analysis times are typically faster, the analysis of large quantities of samples in aqueous solution by combustion does not yield detection limits comparable to CVAAS or CVAFS.

Gases resulting from decomposition are carried through a catalyst furnace to remove halogens, nitrogen oxides, and sulfur oxides. The remaining combustion products, including elemental mercury (Hg0), are then dried in preparation for the detection.

More Information

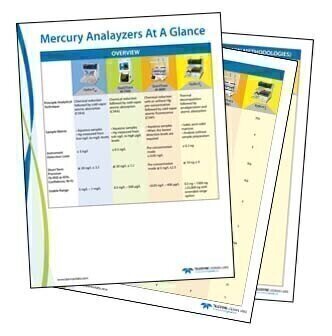

This E-Bulletin is only a brief summary of the variety of considerations when choosing a mercury analysis technique and analyser. Refer to the Teledyne Leeman Lab’s 'Selecting the Best Technique for Mercury Measurement - A Practical Guide', for in-depth information and a questionnaire to assist you in making your choice of techniques. Another tool to aid in determining the best mercury analyser for your application that is available is the Teledyne Leeman Labs 'Mercury Analysers at a Glance' Comparison Guide.

Digital Edition

AET 28.2 April/May 2024

May 2024

Business News - Teledyne Marine expands with the acquisition of Valeport - Signal partners with gas analysis experts in Korea Air Monitoring - Continuous Fine Particulate Emission Monitor...

View all digital editions

Events

Jul 30 2024 Jakarta, Indonesia

China Energy Summit & Exhibition

Jul 31 2024 Beijing, China

2024 Beijing International Coal & Mining Exhibition

Aug 07 2024 Beijing, China

IWA World Water Congress & Exhibition

Aug 11 2024 Toronto, Canada

Aug 25 2024 Stockholm, Sweden and online

.jpg)