Air Monitoring

Trace Analysis of Mercury Using ‘Mercur’

May 24 2013

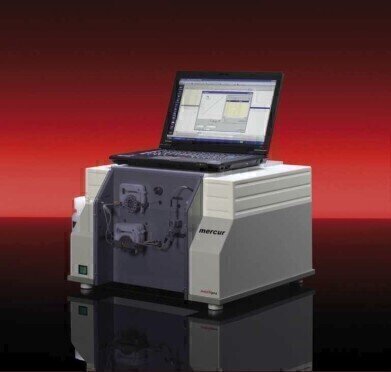

Analytik Jena (UK) will be showing the ‘mercur’ series of trace mercury analysers at ICMGP 2013 stand 25. The ‘mercur’ is a compact system specially optimised for the complete, cost-efficient determination of mercury traces to the ng level. The instrument guarantees mercury analyses in accordance with EPA 1631, EPA 245.1, EPA 245.2, EPA 245.7, EN 1483, EN 12338, EN 13806 and EN 13506.

The ‘mercur’ is available in atomic fluorescence (AFS), atomic absorption (AAS) and combined (DUO) versions. With excellent detection limits and a wide linear measuring range, atomic fluorescence spectrometry is often the method of choice in mercury trace analysis. However, atomic absorption has its advantages for samples in difficult matrices because of its high tolerance towards interferences. The DUO offers the benefits of both techniques, with simple software-controlled change between the two methods.

The mercur utilises the cold vapour technique to convert mercury to the gaseous state by reduction of the dissolved cation with SnCl2. The mercury is therefore separated from the background matrix before transfer to the analysis cell, to reduce interferences and matrix effects. Even further enhancement can be made using simple or cascade enrichment methods. Here cascade enrichment prevents the quenching effect. Enrichment times can be varied to match complex sample matrices or the expected mercury concentration range.

An optional autosampler makes the ‘mercur’ highly automated and easy to operate, with a high sample throughput. Fast analysis is achieved by using continuous flow operation with or without the autosampler plus the unique FBR routine (Fast Baseline Return), which minimises measurement time by increasing argon flow. Automated, intelligent gas-liquid control ensures minimum reagent consumption and short measurement times in various operating modes.

The system is extremely safe through the use of a bubble sensor. If a liquid threatens to spill into the system, this sensor causes the valves to close, and the liquid is automatically transferred to the waste container. Positioned between the gas-liquid separator and a specially optimised drying membrane, it protects the gold collector and the measurement cell against contamination.

Digital Edition

IET 34.2 March 2024

April 2024

Gas Detection - Biogas batch fermentation system for laboratory use with automatic gas analysis in real time Water/Wastewater - Upcycling sensors for sustainable nature management - Prist...

View all digital editions

Events

May 05 2024 Seville, Spain

May 06 2024 Minneapolis, MN, USA

May 13 2024 Munich, Germany

May 15 2024 Lund, Sweden

May 15 2024 Frankurt-am-Main, Germany