Environmental Laboratory

Easy, On-site Measurement of Fats, Oils and Greases in Water Using Portable Mid-infrared (mid-ir) Analyzers

Jun 17 2008

An accurate, quick and simple form of on-site analysis can greatly assist regulators and industries to reduce the build up of fats, oils, and greases (FOG) in sewers. For publicly operated treatment centers, it is important to locate and monitor sites that are suspected of dumping high levels of FOG in the sewer line. Industries need to ensure they are not exceeding their permit limits. Waiting for remote laboratory results can take several days to a week or more.

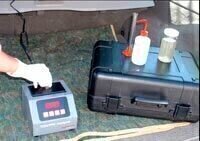

With a simplified FOG analysis procedure using a portable mid-IR analyzer, a regulator or operator can now get an on-site result in less than 10 minutes.

Infrared analysis of oil and grease has been used in the petroleum industry on highly regulated off-shore oil platforms for over 30 years. EPA Methods 413.2 and 418.1 are infrared methods for oil and grease measurement using the now banned Freon to extract the hydrocarbons from the effluent. EPA Method 1664 using hexane as the extraction solvent and gravimetric analysis is now the standard method replacing Freon methods. This gravimetric procedure requires a skilled laboratory technician and is a time and equipment intensive process. The ASTMpassed

an alternate method, D 7066-04, using a Freon replacement solvent, S-316, and simplified infrared analysis.

An alternate infrared method uses hexane extraction and evaporation.

An advantage of infrared analysis is the ease of use and the quick analysis time. Portable, relatively inexpensive fixed filter infrared analyzers such as the Wilks Enterprise (USA) InfraCal TOG/TPH Analyzers, Models HATR-T2 and CVH, allow for on-site analysis for regulators or industrial pretreatment personnel. The extraction and measurement procedure is simple enough for an operator with minimal training to do the analysis.

Using portable infrared analyzers with a simple and quick infrared procedure enables operators of a pretreatment system to easily assess their system’s efficiency. Plant operators can take samples before and after treatment to see how their system functions under heavy loads. System parameters can be changed and the results of the changes can be determined on-site without waiting a week or more for a laboratory result. Regulators from a POTWcan take samples fromthe source and immediately determine who their FOG offenders. Most importantly,

effluent with high levels of FOG that can be stopped before it stops the flow of the sewer line.

Digital Edition

AET 28.3 September 2024

September 2024

Business News - ENVEA announces acquisition of APAQ Group - SICK and Endress+Hauser sign strategic partnership - Efforts to curb gas flaring intensify amid environmental concerns Air Monito...

View all digital editions

Events

WEATHER • CLIMATE • WATER / EARTH OBSERVATIONS / GREEN ECONOMY

Oct 29 2024 St. Petersburg, Russia

Oct 30 2024 Hong Kong

Nov 05 2024 Toronto, Canada

Nov 05 2024 Rimini, Italy

Nov 06 2024 Ho Chi Minh City, Vietnam