-

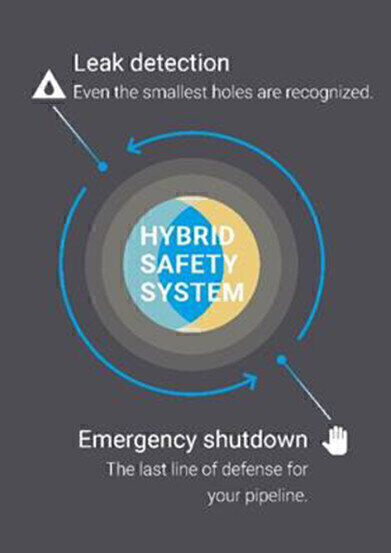

The innovative FlexSILon PMC hybrid system combines leak detection and localisation with emergency shutdown (ESD) capability for safe system shutdown, all integrated into a safety controller.

The innovative FlexSILon PMC hybrid system combines leak detection and localisation with emergency shutdown (ESD) capability for safe system shutdown, all integrated into a safety controller.

Safety

A New Dimension in Pipeline Safety Unveiled in Berlin

Apr 25 2017

At this year's Pipeline Technology Conference in Berlin HIMA Paul Hildebrandt unveiled the world's first SIL 3 capable leak monitoring system. The safety specialist presented the innovative Pipeline Management Control (FlexSILon® PMC) hybrid solution based on a SIL 3 safety controller, with integrated safe leak detection and leak localisation capability. In his presentation session Peter Sieber (Vice President Global Sales at HIMA) described how safety-oriented monitoring systems can significantly reduce leak-induced downtime and risks to people, facilities and the environment.

There are many potential causes of damage to pipelines. Along with material failure, corrosion and wear, pipelines are threatened by theft, terrorist attacks and the increasing risk of cyber attacks. In his expert presentation “Pipeline Leak Detection System and Safety,” Peter Sieber described the relationship between functional safety and leak detection in light of growing digitalisation. He also explained how combining these two disciplines helps operators of pipelines in refineries and chemical plants as well as overland pipelines to improve their safety and cyber security. The innovative pipeline management solution integrates into a safety controller high-availability leak detection and localisation with emergency shutdown (ESD) capability for safe system shutdown.

HIMA designates this hybrid system “FlexSILon PMC” and offers it as a complete pipeline management automation solution. In addition to protecting the facility, this unique package solution controls and regulates safety-related processes for uninterrupted operation over the entire life cycle. It can continuously monitor pipelines, shut them down automatically in hazard situations, and prevent or significantly reduce damage. Thanks to this functional integration, FlexSILon PMC enables reliable and cost-effective pipeline operation while conforming to all relevant standards.

Along with the automation components necessary for control, regulation and monitoring of gas and liquid pipelines, the solution includes customer support and service. It significantly increases the safety and profitability of pipelines by quickly and accurately detecting and localizing leaks, thereby reducing false alarms and downtime. Pipeline operators benefit from higher availability, lower liability and consequential cost risks, and avoidance of environmental damage and loss of reputation. As a closed system with integrated security, FlexSILon PMC also provides significant defense against cyber attacks.

Digital Edition

PIN 25.2 Apr/May

April 2024

In this Edition Safety - Carbon monoxide toxic and flammable gas detection Analytical Instrumentation - Density: A fundamental parameter at critical stages within the petroleum sector...

View all digital editions

Events

May 03 2024 Seoul, South Korea

May 05 2024 Seville, Spain

May 06 2024 Riyadh, Saudi Arabia

May 06 2024 Houston, Tx, USA

May 06 2024 Houston, Tx, USA

.jpg)