Laboratory Products

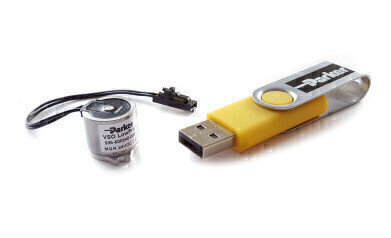

Miniature Valve Delivers High Performance in a Compact Form for Medical Device Applications

Jul 21 2016

Parker Hannifin has unveiled its VSO® LowPro miniature proportional valve for controlling the flow rate of inert gases in medical equipment. Just 16mm wide by 14mm tall, the valve addresses a key requirement for small portable devices where installation space is at a premium. Typical applications for the new valve include pressure control, volumetric flow control and pulse dose control in devices such as portable oxygen concentrators, ventilators and patient monitors.

With the VSO® LowPro reliability is assured with operations up to 25 million cycles, thus delivering that much needed peace of mind. By their very nature, portable medical devices also need to consume low power and feature high performance, this valve series delivers in these two vital areas. The VSO® LowPro miniature proportional valve offers typical flow rates of up to 45 SLPM with a maximum of 2W power at room temperature. What’s more with an orifice of up to 2.03 mm and a weight of 12 g, the VSO® LowPro can perform the function of valves three times its size without sacrificing power.

The new valve features a low profile design which simplifies mounting and eliminates cartridge configurations that require complex and expensive machining, thus keeping a tight control on cost. Compliant with REACH, RoHS, CE, ISO 10993 and ISO 145001, three voltage models are available, 5, 12 and 24 VDC. The two-way, normally closed VSO® LowPro valve is designed to handle air, oxygen or any non-reactive, non-condensing gases. Very low power, typically 1W, enables portable capability and allows designers to reduce the size of the power supply or battery.

The VSO® LowPro valve can be controlled by either voltage or current; however, it is recommended that current control be employed to ensure the most repeatable valve flow performance. For PWM (pulse width modulation) control, the signal applied to the valve should have a frequency of between 5-12 kHz, with the optimum frequency dependent on the application.

Digital Edition

Lab Asia 31.2 April 2024

April 2024

In This Edition Chromatography Articles - Approaches to troubleshooting an SPE method for the analysis of oligonucleotides (pt i) - High-precision liquid flow processes demand full fluidic c...

View all digital editions

Events

May 05 2024 Seville, Spain

InformEx Zone at CPhl North America

May 07 2024 Pennsylvania, PA, USA

May 14 2024 Oklahoma City, OK, USA

May 15 2024 Birmingham, UK

May 21 2024 Lagos, Nigeria

.jpg)