Health & Safety

Lower Cost of Ownership, Lower Risk of Contamination and Increased Levels of Safety

Sep 09 2012

Sellafield Ltd is responsible for safely delivering decommissioning, reprocessing, nuclear waste management and fuel manufacturing activities across sites at Sellafield in Cumbria and Capenhurst in Cheshire.

The situation

The main calibration needs at the Sellafield site in Cumbria are related to pressure, temperature and flow measurements. The site itself has approximately 6,000 instruments that must be calibrated annually.

“It’s all about ensuring safety and taking care of the community”, a Senior Engineer explains the philosophy of calibration. Calibrations are performed at the Sellafield site according to an annual maintenance plan. All calibration results are documented on calibration certificates, which are accessible for audits. The site also keeps records of what has been calibrated, when and by whom.

Calibrations are performed at the Sellafield site to meet various objectives. First of all, regulatory requirements and standards demand periodic calibrations; the industry is heavily regulated. In addition, the sites’ calibration and maintenance procedures are audited on a regular basis. Secondly, and perhaps more importantly, calibration is a matter of safety. In a nuclear plant like Sellafield, the accuracy and reliability of measurements are essential.

One of the most costly and challenging issues that complicate performing calibrations at the Sellafield site in all the maintenance and calibration procedures relates to cleaning the equipment and making sure that it is not contaminated when being moved from one location to another. This is a constant challenge when the equipment is needed in another section of the site or when the equipment must be recalibrated or serviced.

According to the site, the biggest selling point and benefit of a Beamex® (UK) calibrator is that it is designed so that it can be easily moved from one area to another, without the risk of contamination and this brings major cost-savings and allows the recalibration and service of Beamex® equipment to be done efficiently. The site also makes full use of the Beamex® calibrator’s accuracy, stability, complete functionality and robustness.

The solution and main benefits

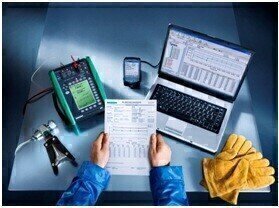

The calibration technicians at the Sellafield site utilise the complete range of Beamex® MC series calibrators for performing calibrations, particularly the Beamex® MC6, MC5, MC4 and MC2 Calibrators.

The site considers that the ideal calibrator from their perspective is robust and easy to use, but still it should have a lot of functionality integrated into one piece of equipment. They describe the criteria for selecting calibration equipment: If the equipment has a complicated design, it can easily collect liquid or other substances. If we have to use several different devices instead of one all-in-one device, the recalibration and maintenance costs are much higher. In addition, if multiple devices are required to perform calibrations, it means that the technicians must be trained for all those various devices.

The Beamex® MC5 Multifunction Calibrator serves Sellafield’s purposes well. The main benefits are accuracy, robustness, integrated functionality as well as the resistance to contamination.

The Beamex® multifunction calibrator integrates several devices into one, which means that Technicians need to learn to use only one device and site needs to only recalibrate one device instead of several. The all-in-one capabilities of the Beamex® calibrator means also that technicians don’t have to run back and forth to the calibration facility in order to change equipment, they can perform most of the calibrations with one device.

Digital Edition

IET 34.2 March 2024

April 2024

Gas Detection - Biogas batch fermentation system for laboratory use with automatic gas analysis in real time Water/Wastewater - Upcycling sensors for sustainable nature management - Prist...

View all digital editions

Events

Apr 30 2024 Melbourne, Australia

Apr 30 2024 Birmingham, UK

May 03 2024 Seoul, South Korea

May 05 2024 Seville, Spain

May 06 2024 Minneapolis, MN, USA