Gas Detection

What is the best gas detection technology for water treatment plants?

Jul 19 2021

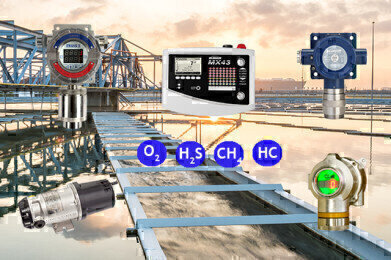

There are several important factors to consider when choosing the right gas detection technology for water and wastewater treatment plants. The ideal detector will be simple to operate and maintain and provide reliable and accurate results. Teledyne Gas & Flame Detection have decades of experience in providing a wide range of gas detection products with an impressive variety of practical sensor technologies to cater for all possible scenarios encountered at treatment plants.

Wastewater treatment generates flammable and toxic gases including methane and hydrogen sulphide. Oxygen enrichment and ozone are also ubiquitous hazards in cases where they are used in the treatment process and carbon dioxide, a potentially toxic gas which can also cause oxygen deficiency, is also used for pH control.

Other toxic hazards, like ammonia and chlorine, are widely used for producing safe drinking water, so reliable leak detection technology is vital to ensure that they gases are not discharged from storage tanks or the processing equipment itself.

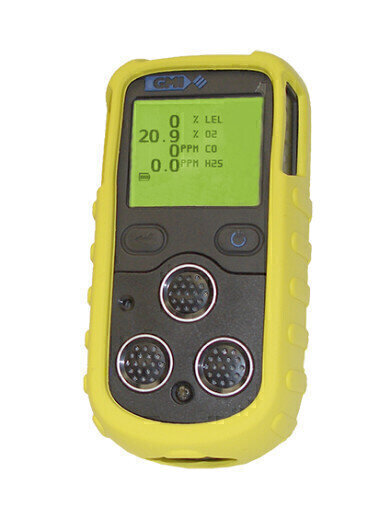

Personnel at water treatment facilities need reliable and robust portable gas detectors as part of their personal protective equipment. Teledyne Gas & Flame Detection has an extensive range of portable gas detectors which are perfect for use in confined spaces and have been created especially for the water treatment sectors.

The best solution is to combine portable and fixed detectors. With Fixed gas detectors operators can enhance their process automation system by improving on their risk management whilst reducing operational costs with little or no human intervention.

Selecting the right gas detectors not only protects personnel and assets it also saves money. Hydrogen Sulphide, as an example, is corrosive to certain metals including steel, brass and copper, so choosing a gas sensor encased in a stainless steel housing is the best course of action.

Deciding what kind of gas sensor is to be used is also crucial – should you opt for electrochemical, semiconductor, infrared (IR) or catalytic technology?

Electrochemical sensors seem to be the favourite choice at treatment plants monitoring oxygen deficiency or enrichment, or wishing to detect low levels of toxic gas es like, for instance, hydrogen sulphide or chlorine. One such sensor in high demand is the Teledyne DGi-TT7-E intelligent gas detector. This highly user-friendly detector incorporates a daylight-readable alphanumeric display that shows the operator local statuses and alarm levels.

Semiconductor sensors are capable of a longer life in harsher environments than their electrochemical equivalents, so they are widely used in hotter or more humid settings and where there is a likelihood of high concentrations of hydrogen sulphide. Many water treatment plants opt for the Teledyne CTX 300 fixed gas detector for oxygen, carbon dioxide and other toxic gases because of its strength of signal stability, sensitivity and long lifespan. This instrument detector can transmit data in record time and, with its pre-calibrated sensors and optional LCD display, is simple to maintain and operate.

IR (infrared) sensors are ideal for detecting explosive gas such as methane or carbon dioxide and for operation in highly corrosive locations with a significant presence of hydrogen sulphide. The measurement works on the principle that every gas absorbs light at a unique wavelength within the IR spectrum. Teledyne’s IR sensors are so robust that only one maintenance run is required per year and they carry a five year warranty. The Teledyne GD10 series IR gas detector is unique in that it uses a silicon based solid-state IR source with a fifteen year warranty. Teledyne’s total confidence in these products has enabled them to offer the longest combined detector and IR source warranty on the market.

The most popular alternative to an infrared sensor is a catalytic model, while it is not as rugged as its IR cousin, it uses considerably less power, making it ideal for remote treatment plants that use solar power. A widely used option is Teledyne’s DG-TX7 intelligent gas detector which features two OXYCOL catalytic sensors.

Teledyne Gas & Flame Detection also offer sampling kits for the water treatment sector, for locations such as areas highly saturated in hydrogen sulphide.

It is vital for water treatment plant operators to choose the right instrument for their specific needs. The gas hazards encountered in the water industry demand that only the most reliable and accurate instruments should be deployed. This can prove to be a difficult choice, so Teledyne Gas and Flame have the expertise to ensure that the rigjht detector is chosen for the right application.

As with all gas detection tasks in the water treatment sector, it is essential to ensure the technology is adapted to the application. Strong concentrations of gas, either immediate or accumulating over time, along with harsh and/or corrosive operating environments, demand proven products. But each application is different, so consulting with a specialist such as Teledyne Gas & Flame Detection is vital in defining the optimum solution for any particular requirements.

Digital Edition

IET 34.2 March 2024

April 2024

Gas Detection - Biogas batch fermentation system for laboratory use with automatic gas analysis in real time Water/Wastewater - Upcycling sensors for sustainable nature management - Prist...

View all digital editions

Events

Apr 22 2024 Hannover, Germany

Apr 22 2024 Marrakech, Morroco

Apr 23 2024 Kuala Lumpur, Malaysia

Apr 23 2024 Kintex, South Korea

Apr 23 2024 Edmonton, AB, Canada