Environmental Laboratory

Introduction to the Quality Assurance of CEMS

Nov 14 2018

Industrial plants undertake continuous emission monitoring for process control and compliance with environmental permits. This is in accordance with EN Standards, and Gasmet has published a Blog covering the 4 stages of BS EN 14181 (2014): QAL1, QAL2, QAL3 and AST (Annual Surveillance Test).

Quality Assurance of CEMS ensures safety and clean emissions

EN14181 was first introduced in 2004 and updated in 2014 to ensure that large combustion and waste incineration plants meet the required criteria. EN 14181 sets the quality criteria for permanently installed measuring equipment at industrial plants. The quality assurance of Continuous Emissions Monitoring Systems (CEMS) is divided into four Quality Assurance Levels: QAL, QAL2, QAL3 and AST.

QAL1 - Quality Assurance Level 1 - Measuring Procedure Check

QAL1 requires that instruments are shown to be fit for purpose, based upon a set of laboratory and field procedures, as set out in the EU Standard EN 15267. Testing must be carried out by an approved laboratory accredited to EN ISO/IEC 17025 (such as TUV or SIRA / CSA) by a national body.

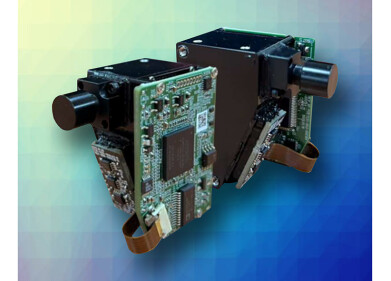

QAL1 assesses the analyser system itself (such as an FTIR), as well as the sample delivery and sample conditioning system (sample probe, sample lines etc.), so it is an assessment of a complete measuring system. A QAL1 certificate is granted by SIRA (for MCERTS in the UK) and / or UBA/TÜV.

When assessing a QAL certificate, a key issue is the certified ranges compared with the daily emission limit value (ELV) of the intended application.

QAL2 - Quality Assurance Level 2 - Installation

The requirements of QAL 2 cover the calibration of the CEMS / AMS against nationally approved analytical methods applied by a test organisation accredited to EN ISO/IEC 17025 (MCERTS in the UK) by a national body. This stage of quality assurance specifies the procedures to ensure that the CEMS has been correctly installed, calibrated by comparison measurement, and independently verified.

The QAL 2 procedure comprises:

- Installation

- Functional test(s)

- Parallel measurements with the Standard Reference Method (SRM) for each parameter (as defined in the site’s Environmental Permit)

- Data evaluation

- Calculation of variability of the AMS measured values

- Test of variability of the AMS measured values and validity of the calibration function

- Reporting

- Inputting QAL 2 Calibration Factor(s)

The laboratory performing the SRM measurements shall be accredited for this task according to EN ISO/IEC 17025, or shall be approved directly by the relevant competent authority.

Typically QAL2 tests are undertaken every 5 years (as defined in a site’s environmental permit), or when there is a major change in the process.

QAL3 - Quality Assurance Level 3 - Ongoing Monitoring

QAL3 is the ongoing monitoring of a CEMS by the process operator; checking the drift in zero/span for example.

AST - Annual Surveillance Test

The AST is similar to QAL2 but is carried out on a smaller scale. These mini-QAL2 tests are functional laboratory spot tests that check the performance and calibration of a CEMS, covering:

- 1. functional test

- 2. parallel measurements with the SRM

- 3. data evaluation

- 4. calculation of variability of the AMS measured values

- 5. test of variability of the AMS measured values and validity of the calibration function

- 6. reporting

Digital Edition

IET 34.2 March 2024

April 2024

Gas Detection - Biogas batch fermentation system for laboratory use with automatic gas analysis in real time Water/Wastewater - Upcycling sensors for sustainable nature management - Prist...

View all digital editions

Events

Apr 22 2024 Hannover, Germany

Apr 22 2024 Marrakech, Morroco

Apr 23 2024 Kuala Lumpur, Malaysia

Apr 23 2024 Kintex, South Korea

Apr 23 2024 Edmonton, AB, Canada