Environmental Laboratory

New Tool for Acoustic Trouble Shooting in the Aerospace, Automotive and Industrial Manufacturing Industries

Dec 15 2014

Currently celebrating its 20th anniversary, AcSoft (UK) used its Acoustic Seminar held on 2nd December 2014 to launch Microflown’s 3D Scan and Paint for acoustic trouble shooting and sound source location in the aerospace, automotive and industrial manufacturing industries.

Recently appointed as Netherlands-based Microflown Technologies’ exclusive UK distributor, AcSoft’s new 3D Scan and Paint system allows easy and accurate visualisation of stationary sound fields in broad frequency range. It is aimed at environments where anechoic conditions are not applicable, such as within manufacturing facilities, engine bays or car / aircraft interiors.

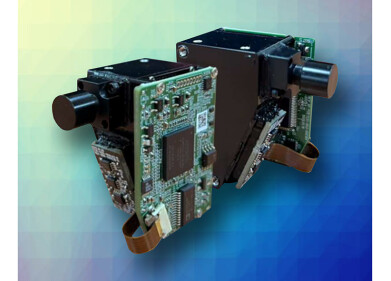

Using the special properties of the Microflown particle velocity probe, which is the world’s first and only MEMS (Micro-Electrical Mechanical Systems) technology-based sensor, AcSoft’s original Scan and Paint has enabled sound engineers to accurately locate, visualise and analyse sound sources without the need for expensive special acoustic environments such as anechoic chambers. The system uses a single probe to scan an object of interest meaning system costs are much lower than similar technologies using acoustic camera arrays.

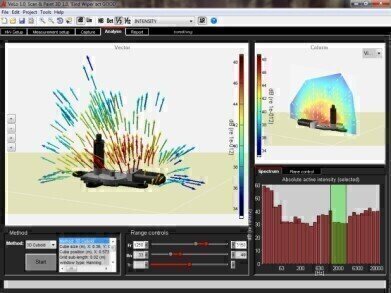

AcSoft’s new Microflown 3D Scan and Paint allows a 3D CAD model to be imported and registered with the 3D camera view. Objects can also be digitised using the probe in the kit which is ideal for when CAD data is not available such as when benchmarking.

The tracked probe is then used to scan the object and sound vectors are displayed in real time giving important information on how sound propagates from a source.

The software allows the sound field to be analysed in detail such as by taking 3D slices through space and exporting data and images to other packages for further analysis and reporting.

The system also provides broadband measurement from 20Hz to 10kHz so all of the significant audible frequencies are covered. The system is largely unaffected by ambient conditions so special acoustic environment is not required.

AcSoft’s 3D Scan and Paint is ideal for a wide range of applications within the aerospace and automotive industries. These include sound source location, leakage and drivetrain analysis, cabin noise location, infotainment design and development, acoustic insulation, HVAC, damping material design and engine noise.

It is also suitable for the industrial manufacturing sector where it can be used for sound source analysis of HVAC, pumps, fans, motors, white goods, tools, speakers and medical equipment.

The Microflown probe is not affected by background noise or reflections so is especially suited to environments where there is a high sound pressure over sound intensity ratio. It allows direct measurement of sound pressure, particle velocity, sound intensity, sound power and the acoustic impedance.

Digital Edition

IET 34.2 March 2024

April 2024

Gas Detection - Biogas batch fermentation system for laboratory use with automatic gas analysis in real time Water/Wastewater - Upcycling sensors for sustainable nature management - Prist...

View all digital editions

Events

Apr 30 2024 Melbourne, Australia

Apr 30 2024 Birmingham, UK

May 03 2024 Seoul, South Korea

May 05 2024 Seville, Spain

May 06 2024 Minneapolis, MN, USA